Dry waste management system

Our range of recyclable and non-recyclable dry waste treatment units includes standard units for smaller installations as well as tailor made units for larger installations. Bvac’s dry waste portfolio includes compactors, glass crushers, shredders and briquetting units. Dry waste management systems manage mixed or recyclable waste in a way that is safe, environmentally friendly, and energy efficient, reducing the volume through compaction and shredding.

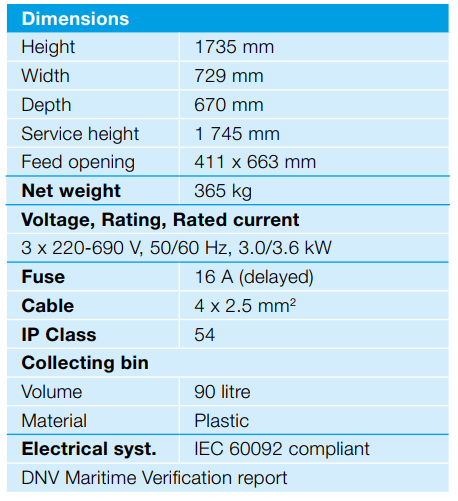

Bvac U80 glass crusher

The Bvac U80 glass crusher is a user-friendly solution for processing waste glass that only produces a minimal amount of glass dust. Bottles are manually fed through the feed pipe and the glass pieces are collected in a standard 80-liter wheelie bin. The crusher starts automatically when the lid is lifted and a timer function ensures that all bottles fed into the unit are crushed, with a volume reduction of approximately 80%. The user is fully protected from being hit by glass splinters even when the feeding door is open. The unit is fitted with a level indicator that automatically stops the crusher when the bin is full. By using different bins it is possible to separate uncolored and colored glass. The crushed pieces are about 40 mm in size, making them suitable for recycling because it allows the detection of ceramics, which prevent glass from melting.

Benefits

- Volume reduction of approximately 80%

- Dust-free operation

- Highly durable crusher head constructed from HARDOX steel

- Unique robust coupling between motor and knife

- Quiet operation

- Automatic start and stop, and full bin alarm

- Easy to install and maintain

- Safe to use

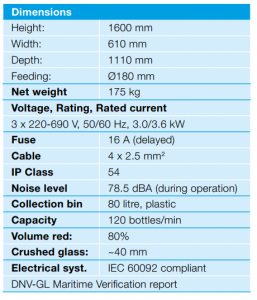

Bvac UMS 2530 mini shredder

The Bvac UMS 2530 is a highly compact unit designed for shredding various materials including general waste, plastic bottles, and aluminum cans. The unit transforms the waste into flakes, which allows any residual liquid to drain away. The Bvac UMS 2530 features slow rotation to keep noise levels to a minimum and a specially designed feeding hopper to ensure safe operation. Depending on the type of waste being processed, the unit can reduce the volume by as much as 80%, which in turn reduces the amount of storage space required. The shredded material is collected in a standard 90-liter wheelie bin for easy handling and transport.

Benefits

- Compact design

- Can shred most kinds of waste

- Highly durable shredder head constructed from HARDOX steel

- Quiet semi-automatic operation

- Automatic reverse if blockage occurs

- Easy to install and maintain, and safe to use

- IEC 60092 compliant electrical system

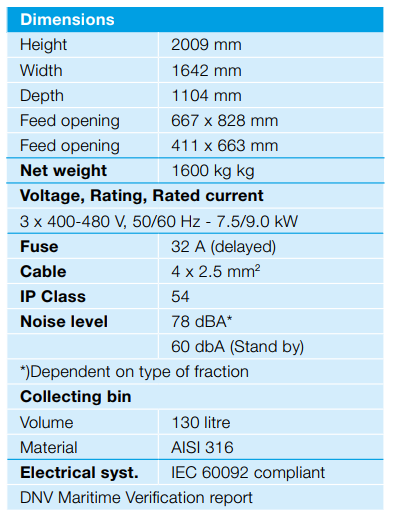

Bvac UMS 5050 midi shredder

The Bvac UMS 5050 is a compact but heavy-duty shredder designed for shredding large volumes of general waste, plastic, metal tins, and wood. The shredder transforms the waste into flakes to minimize volume, allow any residual liquid to drain away, and facilitate incineration. The UMS 5050 features slow rotation to keep noise levels to a minimum and has a large feeding hopper on top of the unit. Depending on the type of waste being processed, the unit can reduce the volume by as much as 90%. For added safety, the unit features an electronic overload control that automatically reverses the shredder when it is overloaded in order to release the material before resuming normal operation. Safety switches on the doors ensure safe access and maintenance. The shredded material is collected in a stainless steel box ready for incineration or transport.

Benefits

- Can shred all kinds of waste including metal tins, plastic, and wood

- Highly durable shredder head constructed from HARDOX steel

- Quiet semi-automatic operation

- Automatic reverse if blockage occurs

- Easy to install and maintain, and safe to use

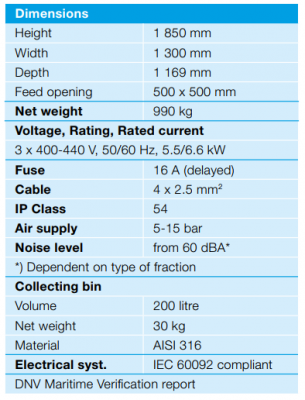

Bvac USC 2020 shredder compactor

The Bvac USC 2020 is a shredder that compacts the shredded material directly into a box. It is a heavy-duty machine that can shred all kinds of waste including soft and hard plastic, wood, cardboard, glass, and metal cans. The single-shaft unit crushes the waste instead of cutting it, which means it can be used to reduce the volume of glass waste. The unit has flexible anvil teeth made of highly wear-resistant steel that do not need to be re-sharpened, with a swing-back function to allow solid objects such as large pieces of metal to pass through without blocking the machine. The USC 2020 features slow rotation to keep noise levels to a minimum and has a feeding hopper on top of the unit. Depending on the type of waste being processed, the unit can reduce the volume by as much as 90%. Safety switches on the doors ensure safe access and maintenance.

Benefits

- Can shred all kinds of waste including metal tins, plastic, glass, and wood

- Shredding and compacting combined in one unit

- Flexible anvil shredder protection

- Highly durable shredder head constructed from HARDOX steel

- Quiet semi-automatic operation

- Easy to install and maintain, and safe to use

The Bvac briquetting unit is an advanced waste compaction system for minimizing the storage volume of dry waste in buildings. The unit includes a shredder, fire gate, shredded waste storage tank, and briquetting machine.

Benefits

- Very high compaction rate (10:1 bulk density)

- Minimal manual intervention required

- Produces clean, compact briquettes with low fire risk

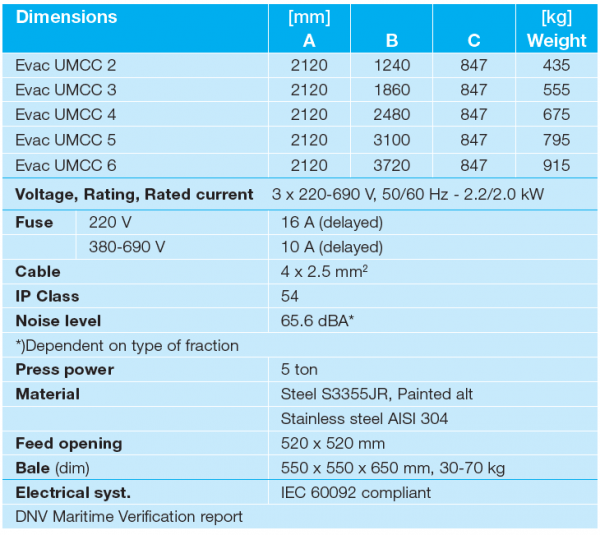

Bvac UMCC multi chamber compactor

The Evac UMCC, multi chamber compactor, can separate and compact several different waste fractions. The compactor has unique double-stroke and stay-n-hold functions for an increased compaction rate. The press head has a proven press force of over five tons.

The general waste is compacted in plastic bags, while plastic film and cardboard are baled and tins and cans compacted. Each Bvac UMCC is tailor-made to suit the needs of the individual customer. The compactor can have two to eight chambers, and additional chambers can be added later if required.

The Bvac UMCC is electromechanical, meaning it is quiet and there is no hydraulic oil leakage or mechanical deterioration over time. It features plug-and-play installation with automatic phase order control. An indication is given when a chamber is full.

The waste volume reduction is up to 90% and the weight of the bales varies between 40 and 70 kg depending on the fraction.

Benefits

- Multi chamber for segregation in up to 8 chambers, each 0.2 m³

- Multi chamber for segregation in up to 8 chambers, each 0.2 m³

- Efficient, clean and silent electromechanical drive, not hydraulic

- “Double-stroke” and “Stay-n-Hold” functionality

- 5 ton pressing power – up to 90% volume reduction

- Easy to retrofit; “Plug-n-Press” installation

- Cost-effective treatment of fractions in a single unit

- No deterioration in efficiency after years of operation

- Storm position feature of press head

- Safe operation in high seas, no moving parts

- Compaction both in sack and bale

- Proven for operation at 22.5 degrees inclination

- Tested for handling of 25 ltr steel paint drums

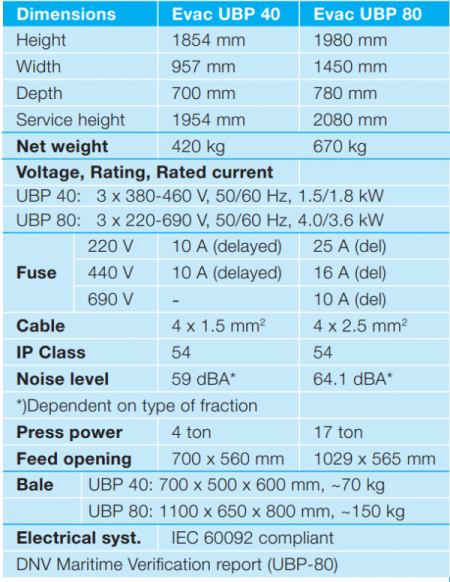

Bvac UBP baling press

Cardboard is easy to send for recycling if properly compacted and this also reduces the disposal cost. The robust Bvac UBP baling presses with the electromechanical drive designed for easy maintenance and contain no hydraulics. The Bvac UBP features plug-and-play installation with automatic phase order control and an indication is given when a chamber is full. The Bvac UBP comes in two sizes, 40 and 80.

The Bvac UBP 40 is a compact, durable, and easy-to-maintain bailing press for cardboard. The compacted cardboard is strapped together with two plastic ribbons. The compactor has unique double-stroke and stay-n-hold functions for an increased compaction rate, and the press head has a proven press force of over four tons.

The Bvac UBP 80 is a durable bailing press that is easy to use and maintain. The wide feeding opening eliminates the need to manually pre-compact cardboard before it is fed into the machine. The compactor has unique double-stroke and stay-n-hold functions for an increased compaction rate, and the press head has a proven press force of over 17 tons.

The compacted cardboard is strapped together with four plastic ribbons. The semi-automatic bale ejection makes it easier to handle the bales, which can weigh up to 150 kg and have an approximate volume of 500 liters. The bales are of standard pallet size, making them easy to store and transport with a forklift.

Benefits

- Large inlet for cardboard

- Baling of voluminous recyclable waste

- Semi-automatic bale ejection

- Automatic indication for full bale

- Bale fits on pallet

- Efficient, clean and silent electromechanical drive

- “Double-stroke” and “Stay-n-Hold” functionality

- 15 ton pressing power – up to 80% volume reduction

- No deterioration in efficiency after years of operation

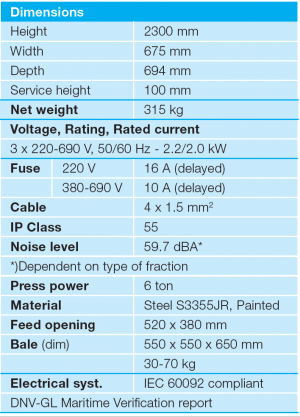

Bvac UBP 30S Combined sack compactor and baling press

The Bvac UBP 30S combines a sack compactor for general waste with a baling press for cardboard and plastic film. The Bvac UBP 30S compacts general waste into cubic plastic bags that are easy to transport. The baling bands can be used as handles, making it easy for crew to handle the bails.

The compactor has unique double-stroke and stay-n-hold functions for an increased compaction rate of over 90%, and the press head has a proven press force of over five tons. The Bvac UBP 30S is electromechanical, meaning it is quiet and there is no hydraulic oil leakage or mechanical deterioration over time. It features plug-and-play installation with automatic phase order control. An indication is given when a chamber is full.

Benefits

- Efficient, clean and silent electromechanical drive

- Compaction in durable plastic sacks

- Compaction and baling in one single unit

- “Double-stroke” and “Stay-n-Hold” functionality

- 5 ton pressing power – up to 90% volume reduction

- No deterioration in efficiency after years of operation

- Over 500 units supplied in recent years

Bvac UKP6060 refrigerated compactor and refrigerated storage unit

The Bvac UKP6060 refrigerated compactor stores compacted waste securely in durable plastic bags. Depending on the type of waste being processed, the compactor can achieve a volume reduction of up to 90%. To prevent odors, the built-in refrigeration unit keeps the stored waste at a constant temperature of 4 °C. The compactor is designed for installation in kitchen areas and is extremely quiet, safe to use, and easy to maintain.

The Bvac URB refrigerated storage unit can be used to store additional bags of compacted food waste. Its standard size corresponds to other kitchen equipment such as refrigerators.

Bvac UD100 dewatering unit

The Bvac UD100 is a patented solution for food waste dewatering that includes screening and separating food waste from sludge. The dewatered food waste is collected in a durable plastic sack. When placed in a refrigerated area, odors from the dewatering unit are minimized by its own ventilation system and the airtight collecting bag.